Adding an inner forestay expands sail plan options and can make for better boathandling.

When my wife, Ellen, and I began our search for an ocean-going cruising boat, high on our list of requirements was that it be a cutter—a simple, single-mast rig with one mainsail and two headsails and a mast set further aft than on a sloop.

The cutter has several benefits. The larger foretriangle allows the total sail area to be proportioned more equally between the three sails. Two ready headsails offer flexibility and efficiency, precluding the hassle of swapping a large genoa for a smaller jib when conditions warrant. The dedicated intermediate stay set aft and closer to the mast permits a staysail in strong winds, and pairing it with a deeply reefed main (or trysail) better balances the helm. And the added forestay offers security when going to windward and makes for easy short tacking in harbors under staysail alone.

Unfortunately, we never found a cutter that satisfied our other requirements. And, when we fell in love with the Lyle Hess-designed Nor’Sea 27, we bought a bare hull and deck to complete in our backyard, figuring we could fairly easily build a cutter rig for it. Our ideas were quickly dashed by Lyle himself. He pointed out that designing and building a cutter rig would result in a domino effect of additional changes that just weren’t worth it.

So, we went sailing on Entr’acte the sloop, and four years later, found ourselves in Portugal anchored next to world-cruising veterans Hal and Margret Roth. Their sloop, Whisper, proudly sported an intermediate forestay they had added, which Hal said provided nearly all of the advantages of a full-fledged cutter. I wondered about doing the same aboard Entr’acte. “It won’t be a cutter,” Hal said, “but it will be pretty close. You just have to be very clever about how you do it—and keep things simple!”

That meeting and conversation came full circle as Ellen and I prepared Entr’acte for our second voyage and debated adding roller furling. An intermediate stay like the Roth’s, we reasoned, would offer redundancy if the headsail furler broke, and it would let us set a smaller headsail in windy conditions, taking the burden off that single headstay.

Attaching an inner forestay between the mast and deck would be easy. Our challenge was to position it correctly to gain the best possible sail plan options and to make it easy to stow when not in use.

Forestay Positions

In the forward position, the stay is attached to a permanent toggle installed in the stemhead fitting’s aft-most opening. The stay is just clear of the furling drum and allows for easy hoisting and lowering of sails.

Our inner forestay would have three positions. The first would attach immediately to the main stemhead fitting just aft of the roller furling drum. In this position we could hank on the 110 percent working jib or a large nylon drifter. This would also be a better location to attach the sliding tack strap of our new asymmetric cruising chute. This strap is designed to wrap around a furled genoa and slide up and down to adjust the shape of the cruising chute’s luff, which might be all right for a Sunday afternoon. But for long passages we did not like the idea of that strap chafing mile after mile on a furled, expensive genoa and imparting needless wear on furling gear bearings for thousands of miles when not in use. Far better to have that tack strap ride on its own forestay to save the wear and tear.

The second position was 3 feet back from the primary forestay. From this position we could set our storm jib as a staysail for short tacking into an anchorage. It would also improve the boat’s handling in heavy winds. As a mainsail is reefed, the length of the foot decreases and moves forward, shifting that sail’s center of effort toward the mast. But when a headsail is furled under the same conditions, its center of effort remains unchanged, so the net movement of the center of effort is forward, which tends to unbalance the helm. Setting a headsail 3 feet further aft brings that sail’s center of effort aft, helping to balance the helm in heavier winds.

The staysail rigged, with the inner stay set in the aft position. To use this, Ed rolls in the genoa and stows the sheets forward, out of the way.

The third position would be stowed for when this stay is not needed. In our case, the wire, detached from its turnbuckle, was just the right length to clip onto a 1⁄4-inch turnbuckle attached to a bail on the starboard middle stanchion. The turnbuckle would provide just enough tension to keep it from slopping around, allowing the stowed stay to serve also as a stable handhold when needed. Attached in a straight line to the stanchion, the new stay would be out of the way until needed with no bends or extra hardware.

Fortuitously, measurements landed the aft attachment point for the new headstay between the two large cleats at the narrowest clear point on the foredeck. This is where the deck is least likely to flex under load, and the foredeck remains clear.

Stay Installation

Deciding where exactly to mount the stay was a product of trial and error with cheap line. We finally determined it was best to mount the deck attachment 3 feet aft of the main stemhead fitting and the mast band 3 feet below the masthead. This positioning would keep the new stay parallel to, and far enough away from, the main forestay to prevent the two from tangling with each other, a common problem with double forestays. With the judicious use of extra toggles, we could easily move the lower attachment point from the fore to aft positions, ensuring it fit perfectly in either location.

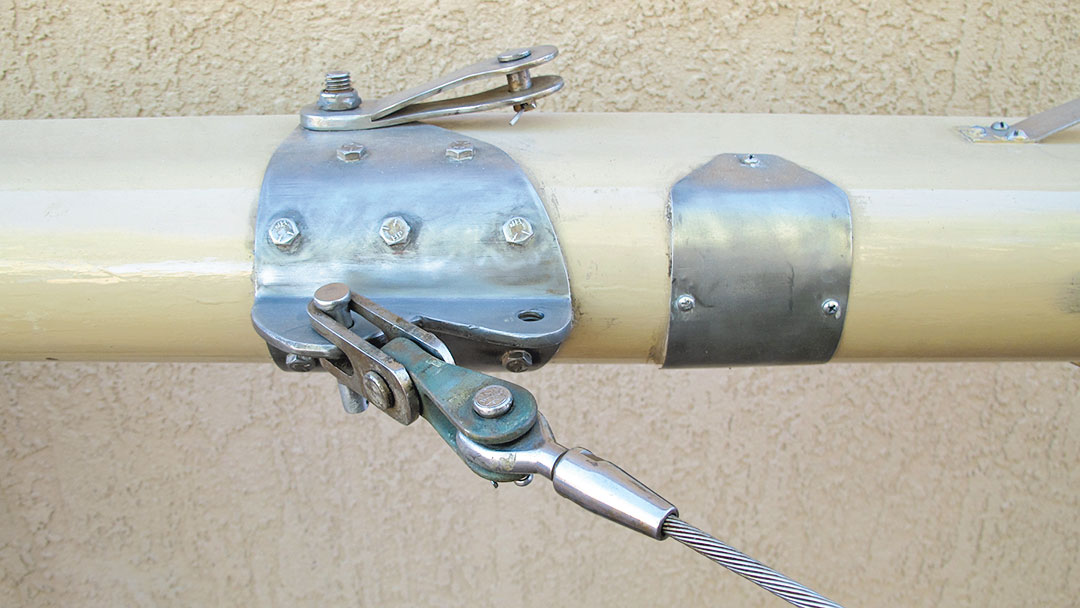

The mast band is attached with 1⁄4 x 20 machine screws drilled and tapped. It’s further secured through a 1⁄2-inch stainless steel stud that passes completely through the mast and compression tube. The stud also provides an attachment for tangs for running backstays.

The standing rig consisted only of the forestay and a 7⁄16-inch bronze turnbuckle. (The price of a proper “highfield lever” to tension the new stay took our breath away. We opted instead for a spare turnbuckle with toggle and quick release pins. Simple, yet effective.)

The running rig was simply a halyard and two jib sheets. We didn’t add additional winches or lead blocks, figuring that both headsails would never be used on the same tack at the same time. When we wanted to hoist a staysail, we employed the unused genoa winch.

Ed added a robust deck plate under the foredeck with an eye to accept a turnbuckle and wire that transfers the load to the foremost interior bulkhead, which is glassed to the hull.

Below decks, we installed a 1 x 6-inch white oak plank which completely traversed the deck. This one large beam effectively increased our deck thickness and served as a substantial backing plate not only for the forestay but for the deck cleats as well. This was a distinct improvement from the two smaller individual backing blocks we had before.

A 1 x 6-inch oak plank added beneath the foredeck replaced two smaller backing blocks and beefed up the entire area where two bow cleats and the forestay are attached.

To prevent leaks and mold, we thoroughly bedded the oak beam and both deck plates with Dolphinite compound. We always use Dolphinite whenever we bed wood to fiberglass or wood to metal because, unlike other compounds, it soaks into the wood to best seal out water. It also boasts anti-fungicidal properties that prevent rot. Dolphinite never gets hard and has always proved easy to disassemble, even after many years in place.

Putting it to Work

Over time we have experimented with the inner forestay and have learned a lot. We discovered an especially interesting setup on our 2003 Atlantic crossing. The wind was in just the wrong place, not quite dead astern but far enough on the quarter so the mainsail completely blanketed the genoa, rendering it quite useless. Poling out the genoa on the other side for a dead run would require a course change 15 degrees to port of our rhumb line. To get the genoa to draw properly would likewise mean a 15- or 20-degree alteration to starboard.

Because of the relatively light wind and pronounced cross swell, the large cruising chute was not a viable option. We certainly could have sailed a day at a time gybing onto alternating tacks, but there had to be a better solution. Finally, we came onto our desired course, trimmed the mainsail and genoa on starboard tack, hoisted our 110 percent working jib as a staysail with the inner forestay in aft position, and poled it out to starboard. Because the jib was small and sailing by the lee, it did not drive us very well, but it did funnel the wind quite nicely into the large genoa, tricking it into drawing properly. Once set, we continued comfortably on our way for the next five days.

Our inner forestay has been a rousing success with results far better than we had imagined. It’s a simple and economical addition to our cruising rig and gives us most of the advantages of a proper cutter. After sailing thousands of miles with this system, the only improvement we might make would be to add a dedicated halyard winch.

Storing the Stay

When it came to storing our inner stay when not in use, we got lucky and were able, by removing its turnbuckle, to attach it to a stanchion with a shorter turnbuckle and provide enough tension to keep it safely snug.

But, storing the inner forestay is usually easier said than done. Once disconnected at the deck fitting, the stay is too long to stow in a straight line from the mast fitting. Bending the stiff and inflexible 1 x 19 rigging wire causes work hardening, which dangerously weakens the wire. If your wire stay is too long to stow in a straight line, it must be led around a large, smooth radius before it is put under tension for stowage.

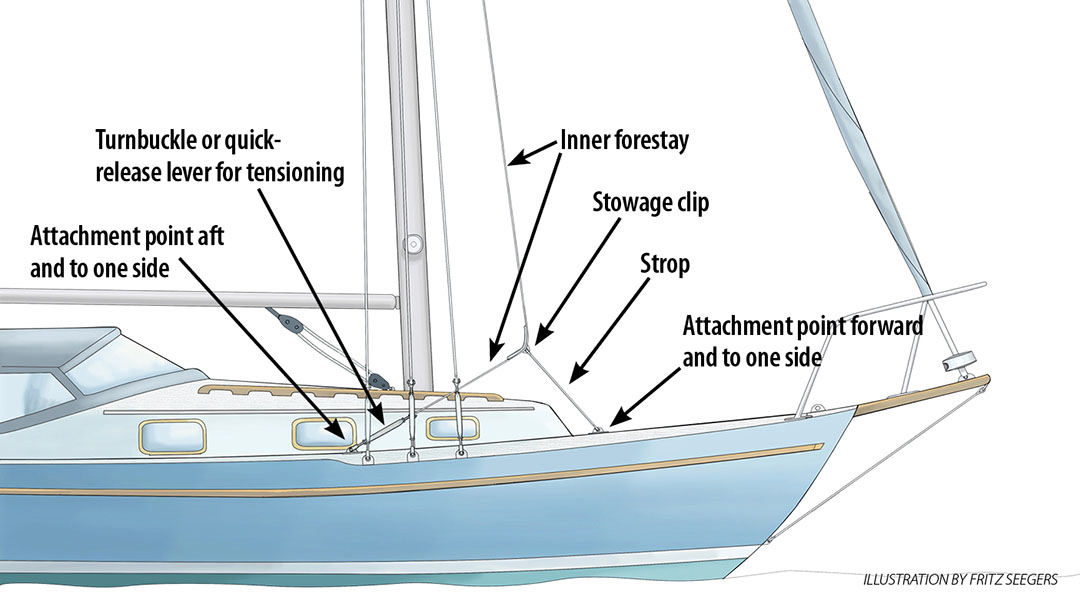

A stowage clip, also known as an inner forestay clip or inner stay storage bridle, solves the problem. This simple piece of gear clips onto the stay and features an eye for a strop that can be used to draw the stay away from the mast. With the strop leading forward to one anchor point on deck, the stay can be tensioned with its turnbuckle to a second attachment point slightly aft.

Wireless Options—Jamie Gifford

An inner forestay adds options for sail plan and mast control. But the location of an inner forestay can mean that it’s sometimes an inconvenience when not in use. It can interfere with tacking or prohibit dinghy storage on the foredeck. Making the inner forestay removeable alleviates some of these drawbacks but creates new challenges. Stowing the detached forestay can be difficult if long length requires deflecting wire around to its anchor point. And once stowed, the stay may bang into the mast and spreaders or chafe against a tightly sheeted genoa.

Using high-strength, low-stretch line instead of traditional wire mitigates these problems.

Dyneema or Spectra line (same fiber, different manufacturers) offers several excellent characteristics for this application. Single-braid construction is very easy to splice. It has a soft hand and is so lightweight that it floats. This makes for easier stowing than wire and less chafing against rig and sail surfaces. These high-tech lines have good UV resistance, with tests revealing that 10 years of exposure degrades the material by about 50 percent. This isn’t insignificant, but stainless steel also degrades (from corrosion and work hardening), and the line is easier to inspect.

All materials have their Achilles’ heel. For these lines, it’s chafe. Though very slippery and chafe resistant, an edgy object pressed against a loaded low-stretch line will damage it quickly. These same lines are available as double-braided and with a polyester cover, but while these features offer some chafe protection and UV blocking, they also are harder to splice and less slippery (important when hoisting/dropping sails). In my opinion, the gains don’t warrant the compromises. It’s best to minimize chafe by attaching sails using soft hanks of either webbing loops or soft shackles (made from Dyneema or Spectra) and to keep running gear from wearing against a low-stretch line stay.

On Totem, the Stevens 47 that my wife, Behan, and our three children circumnavigated on, the removeable inner forestay is made from Dyneema SK75. Three grades of Dyneema have appropriate strength and stretch characteristics for this application: SK75, SK78, and SK90. One-quarter-inch-diameter SK75 has a breaking strength of 8,600 pounds.

Totem also has a removable Solent stay, set parallel and close to the forestay and made from Dynex Dux. This is Dyneema line put through additional treatment that makes it even stronger and with lower constructional stretch.

In sizing Dyneema or Dynex Dux, I recommend increasing the diameter to account for the inevitable UV damage. And splice the ends around a thimble. No knots! Thimble-less or knotted ends result in tight bend radiuses that significantly weaken the line.

High-tech line is a nice solution for a removable inner forestay and has many other applications onboard. And besides, who doesn’t like to show off a little DIY traditional ropework in techy materials?